Ceramic coating application is a precise process that prepares, coats, cures, and polishes surfaces for durable protection and enhanced aesthetics. For vehicles, it complements services like window tinting or custom wraps. Application time varies based on surface size, condition, and coating type, with environmental conditions affecting drying times. Following manufacturer guidelines ensures ideal curing, typically taking 12-24 hours for full protection against UV rays and improved visual appeal.

“Discovering the ideal time for ceramic coating application can transform your vehicle’s protection. This comprehensive guide breaks down the intricate process, revealing key factors affecting duration. From surface preparation to curing, each step is crucial for a durable, glossy finish.

We explore how environmental conditions, material quality, and surface complexity influence application time, offering insights to optimize results. Learn the secrets to achieving a superior ceramic coating in less time, ensuring your vehicle stands out with enhanced protection and aesthetics.”

- Understanding the Ceramic Coating Process

- Factors Influencing Application Time

- Optimizing Coating Duration for Best Results

Understanding the Ceramic Coating Process

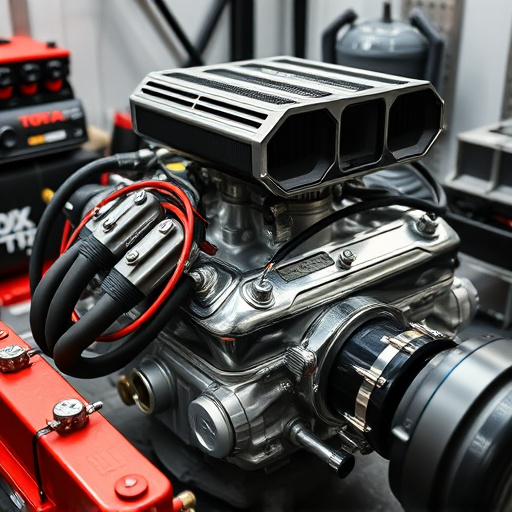

The ceramic coating application process involves several precise steps to achieve a durable and glossy finish on various surfaces, including cars, boats, and even home fixtures. It’s more than just painting; it’s a scientific approach to protection and enhancement. The initial step is surface preparation, where the item is meticulously cleaned and treated to ensure the coating adheres properly. This often includes decontaminating the surface with specialized cleansers to remove any traces of pollutants or residue from previous finishes.

Once ready, a base coat is applied, forming the first layer of protection. This is followed by the star of the show: the ceramic coating itself. Made up of tiny ceramic particles suspended in a solvent, this liquid compound hardens over time to create a seamless, hard-as-glass barrier. The final steps involve curing and polishing, allowing the coating to achieve its maximum strength and shine. This process isn’t just about aesthetics; it offers significant advantages like increased durability, resistance to scratches, and enhanced UV protection—a boon for vehicles, especially when coupled with services like window tinting or custom vehicle wraps and paint protection film.

Factors Influencing Application Time

The time needed for a ceramic coating application varies based on several factors unique to each project. One primary influencer is the size and condition of the surface to be coated—a large, rough, or heavily damaged panel will naturally take more time than a smaller, smoother area. The type of ceramic coating used also plays a significant role; some coatings dry faster than others, affecting the overall application timeline.

Additionally, environmental conditions like temperature and humidity can extend or compress application times. High humidity levels can slow down the drying process, while warmer temperatures expedite it. Custom vehicle wraps and automotive detailing professionals often consider these factors to achieve high-quality finishes, ensuring each step of the ceramic coating application is done meticulously and efficiently.

Optimizing Coating Duration for Best Results

When it comes to ceramic coating application, optimizing the duration is key to achieving optimal results. The ideal time for application varies based on several factors, including the specific coating type, surface condition, and environmental conditions. For best outcomes, adhere to manufacturer guidelines regarding drying times between coats. Generally, a quality ceramic coating can take anywhere from 12 to 24 hours to cure completely, offering long-lasting protection.

A well-timed application process enhances the overall effectiveness of the ceramic coating, providing superior UV protection and high-quality finishes. By allowing adequate time for each step, from preparation to final curing, you ensure a durable and glossy finish that not only protects your vehicle but also adds to its aesthetic appeal. Remember, rushing the process may compromise the quality of the end result.

Ceramic coating application time is a critical factor in achieving optimal results. By understanding the process and the various influences, such as surface preparation, product type, and environmental conditions, you can effectively optimize coating duration. Regularly maintaining and monitoring these aspects ensures a durable and glossy finish, enhancing the overall aesthetic appeal of your coated surfaces.