Ceramic coatings, applied via professional techniques like PPF installation, offer advanced vehicle protection against environmental stressors, UV radiation, acid rain, and extreme temperatures. Their ceramic particles act as protective barriers, enhancing scratch resistance and providing a sleek, durable finish that transforms appearances and longevity. Though costly and requiring expert application, proper techniques ensure high-quality results, making ceramic coating application a valuable investment for car owners.

“Uncover the advanced world of ceramic coating application, a revolutionary technology transforming various industries. This article delves into the science behind this process, exploring its composition and remarkable properties. We break down the application process, from techniques to best practices, ensuring optimal results. Discover the multitude of benefits it offers while also addressing potential challenges. By understanding ceramic coating application, you’ll gain valuable insights into a game-changing solution that promises durability, aesthetics, and enhanced performance.”

- Understanding Ceramic Coating Composition and Properties

- The Application Process: Techniques and Best Practices

- Benefits and Challenges of Ceramic Coating Implementation

Understanding Ceramic Coating Composition and Properties

Ceramic coatings are composed of advanced ceramic particles suspended in a polymer matrix, often combined with additives for enhanced performance. This unique blend offers exceptional durability and protection against environmental factors like UV radiation, acid rain, and extreme temperatures. The key to their effectiveness lies in the ceramic particles, which act as tiny shields, creating a robust barrier that prevents damage to the underlying surface.

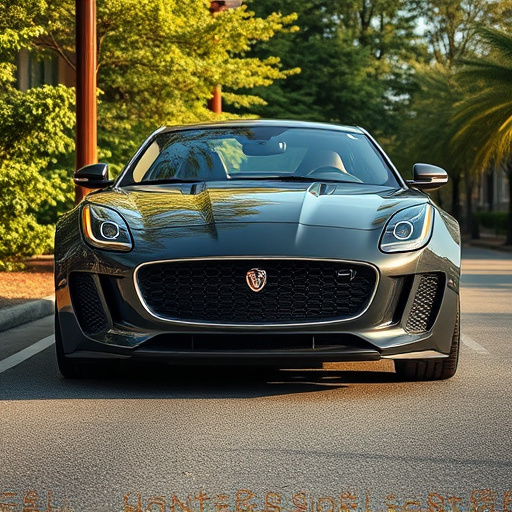

These coatings are renowned for providing high-quality finishes that not only enhance aesthetics but also offer superior scratch resistance. When applied correctly by professionals using precision techniques, such as professional PPF (Paint Protection Film) installation, ceramic coatings can transform the look and longevity of vehicles, providing an alternative to traditional painting methods and vinyl wraps.

The Application Process: Techniques and Best Practices

The ceramic coating application process involves several meticulous steps to ensure optimal results. It begins with thorough surface preparation, where the vehicle’s paintwork is cleaned, decontaminated, and properly dried to create a clean canvas. This critical step is essential for achieving a smooth, long-lasting finish as it eliminates any contaminants that could compromise adhesion. After preparation, the ceramic coating is applied in thin, even layers using professional equipment. Typically, a spray gun or airbrush is employed to precisely control the amount of material laid down.

Best practices during application include maintaining a controlled environment with minimal dust and direct sunlight to prevent premature curing. The use of heat guns or other heating methods may be necessary to ensure complete curing, enhancing the coating’s durability and hardness. When compared to alternatives like paint protection film (PPF) or vinyl wraps, ceramic coatings offer a superior level of protection against environmental factors, UV rays, and chemical damage, making them a popular choice for those seeking extensive and long-lasting automotive care.

Benefits and Challenges of Ceramic Coating Implementation

Ceramic coatings offer a multitude of benefits for vehicle owners looking to enhance their car customization and protect their investment. One of the primary advantages is their superior heat rejection properties, which can help maintain optimal interior temperatures by reflecting radiant heat from the sun. This feature is particularly valuable in regions with hot climates, ensuring passengers enjoy a comfortable ride without excessive overheating. Additionally, ceramic coatings provide an extra layer of protection against environmental factors like UV rays, bird droppings, and tree sap, thereby preserving the vehicle’s paint job and extending its lifespan.

Despite these advantages, implementing ceramic coating application is not without challenges. The process requires specialized equipment and expertise, making it more expensive than traditional waxing or sealing. Furthermore, incorrect application can lead to uneven coverage, leaving some areas more susceptible to damage. However, with proper training and the right products, professionals can overcome these challenges, ensuring a high-quality finish that enhances both the aesthetic appeal and longevity of the vehicle’s exterior.

Ceramic coating application has emerged as a transformative technology in various industries, offering superior protection and enhanced aesthetics. By understanding the science behind its composition, careful consideration of application techniques, and awareness of both benefits and challenges, professionals can harness the full potential of ceramic coatings to deliver top-quality finishes that stand the test of time. This advanced material continues to revolutionize protective coatings, ensuring long-lasting durability and visual appeal across diverse applications.